It's no secret that automation is changing the way we do business. Robots are taking on more and more work, freeing up humans to spend their time elsewhere. And while some people may be scared of what this means for them in terms of jobs, it also has a lot of potential benefits for companies who are willing to take the leap.

Investing in a welding collaborative robot is an investment that will pay off. But how much and when? To answer these two important questions, most people calculate ROI (Return on Investment).

ROI is often used as a way to measure the benefits of automation projects. It tells you if your investment was worth it and what ROAS ( return on assets ) might be achievable with this machine, so do not take its low numbers lightly!

There are many ways to measure ROI, but one of the most common methods is payback. This calculates how much an investment will earn back in salary for your welders over time- or what's called return on investment (ROI). It works by dividing up an expense against their wage bill and considering only tangible benefits like profit margins when evaluating these numbers realistically though. A better way might be looking at intangibles - things that may seem small but have lasting effects down future generations too so shouldn't just get forgotten about!

Calculating the Financial Aspect of Your Welding Cobot

The next step is to crunch some numbers and see how it affects your ROI. When you’re calculating, remember that there's a realistic two-year time frame for results in this calculation; include all factors such as:

- The total cost of the welding cobot system

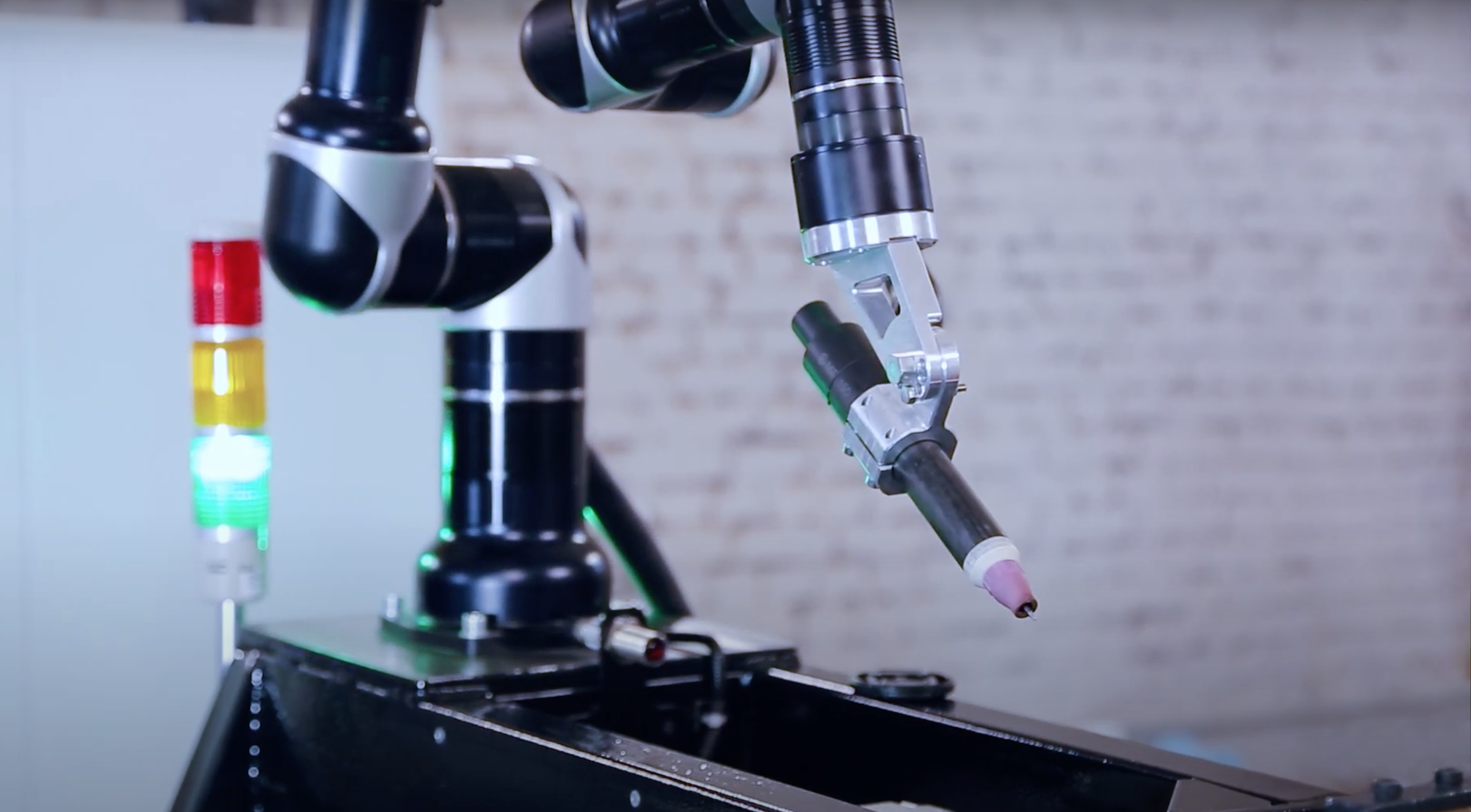

The total cost of the robot welding system can be substantial. You need more than just a cobot, though they're usually only one-third in price; it takes into account necessary machinery and equipment such as presses for metal stock processing or coating lines that will add up quickly with these collaborative robots!

The cobot welding tool has been designed to work in sync with the fixtures and jigs. The fixtures are used for localization of parts, while a special technique is needed on each specific weld joint so that it can be controlled easily by this intelligent machine without any human involvement at all!

You may also have to consider the cost of engineering, programming and installation.

- Working shifts

Working shifts is a big hassle. You need to take into account how often and for how long the robot will work in order calculate its working hours, then multiply that number by your desired shift length per day/week (depending on what you're trying do) before adding up all weeks together over this calendar year - making sure not forget any days off!

One interesting element to consider is that with a fully functioning robot cell, you’ll be able to produce weld parts lights-out! Whether it's for the couple of hours after working days or on night shift full time - productivity gains will have great impact on ROI.

- Labour cost savings

The first variable that is usually considered when calculating the ROI is labor cost saving. You’ll see later on how much more than this there really can be and why it remains an important part of any return on investment (ROI). To get your number, you need to take into account annual wages for employees who will supplement robotic welders with their work at hand; including salary costs as well as insurance benefits

- Maintenance

Collaborative robots will require you to develop an automation team. The members of this group can be assigned programming, jig designs for repairs or maintenance depending on what type of cobots are being used in your factory floor - but the expense should not go unnoticed!

Calculate ROI

By applying the variables listed above, you’ll be able to calculate your payback period and labor/productivity savings.

Payback period = Total Costs / Total Savings per year

It’s not too hard to calculate an ROI when you know the formula. You can use this calculator from Automate.org or one of many others online!

- The intangibles

Intangibles are the benefits of automation that you don’t have a hard value for. You can tell how valuable these intangibles really are though because they will impact your ROI in such a way! There's plenty to go around, so let me take an example:

- Production stabilty

Collaborative robots are the future of manufacturing. With one weld, they can deliver consistency in your raw materials and save you money by not having to buy extra supplies for each task that is performed on the factory floor. As well as being able to give many tasks at once without interruption or exhaustion from repetitive motion injuries.

- Safety of your employees

Welders can suffer from work-related problems. This includes minor lung irritation to life-threatening cancer, depending on how often they are exposed and what substances enter their lungs when welding for long periods of time in an environment filled with toxic fumes like metals cutting against each other at high speeds under pressure (like things we weld all day!). Automating these processes using collaborative robots has been shown to decrease your employees’ exposure by as much 97%. The result? Better health, less risk.

- Efficiency is improved

With cobots, your experienced welders can do more significant and critical tasks that are worth their experience. With the same amount of workers you get better value for business because these high-value jobs will set up new opportunities instead of being limited by doing monotonous work all day long on just one task.

- More return customers

No matter who you ask, having a cobot on your factory floor looks very high-tech and impressive. Not only will they be impressed with how fast it works but also the quality of work that is produced in such little time!

When you look at your ROI, don't forget to consider all the clear costs and savings we discussed. But do not include any intangible benefits either! Together they will give an accurate picture of cobot's value proposition for customers.